Case study

Optimizing Wafer Inspection with Air Bearing Motion Stages

In the fast-paced world of chip manufacturing, every stage of the process demands precision and reliability. Among these critical stages, wafer inspection stands out as a crucial step in ensuring the high quality and reliability of final products.

LAB Motion Systems offers a range of high-performance air bearing stages tailored to meet the unique challenges of wafer inspection, catering to both unpatterned and patterned wafer inspection requirements.

Patterned wafer inspection, in particular, poses challenges due to the need for high precision and fast settling times while handling delicate substrates.

LAB Motion Systems recognized the need for advanced motion stages capable of meeting the demanding requirements of patterned wafer inspection.

Solution: XYTZ stage.

To address this challenge, we developed a specialized solution that combines our low-profile designed XYTZ stage with an active vibration isolation system and advanced motion control system. This integrated system ensures ≤50ms settling time within a ±100nm position error band, providing the speed and precision required for efficient patterned wafer inspection.

Our tailored solution for patterned wafer inspection was applied seamlessly. The low-profile design of our XYTZ stage minimizes footprint while maximizing stability, ensuring precise motion control even in confined spaces. The active vibration isolation system enhances stability by reducing the effects of external vibrations and those generated by the motion system itself, while the advanced control system optimizes for high acceleration and settling time.

Results.

The implementation of LAB Motion Systems’ air bearing stages for patterned wafer inspection has delivered significant improvements in inspection efficiency and accuracy. Manufacturers have reported faster inspection times, reduced downtime, and improved yield rates, leading to enhanced productivity and cost savings. By providing a reliable solution for patterned wafer inspection, LAB Motion Systems has helped chip manufacturers maintain their competitive edge in the industry.

In the complex landscape of the semiconductor industry, LAB Motion Systems’ air bearing motion stages have emerged as a vital tool for enhancing wafer inspection processes. Our optimized solution for patterned wafer inspection enables manufacturers to overcome today’s challenges, as defined by Moore’s Law, while still achieving best-in-class performance and quality. As the industry continues to evolve at a rapid pace, LAB Motion Systems remains committed to providing innovative solutions that drive success in the semiconductor industry.

To learn more about how LAB Motion Systems’ air bearing motion stages can enhance your wafer inspection processes, contact us today.

“We realize complete integrated motion systems for a variety of industries and clients.”

Gilles Gords – Manager Linear Products

Featured products

More products

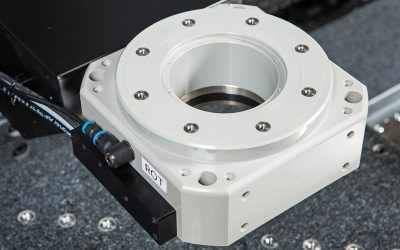

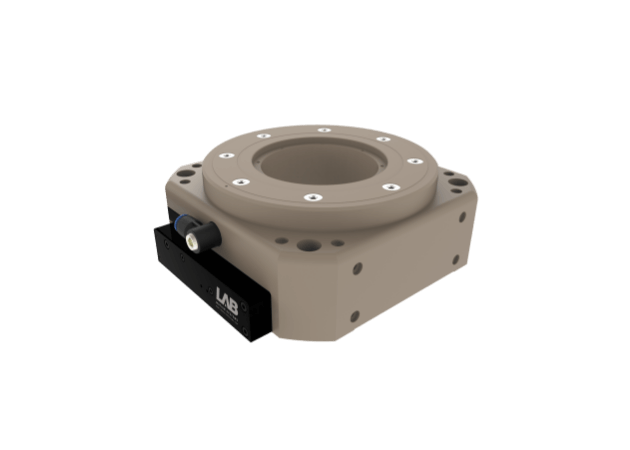

RT150AX

Drivebox

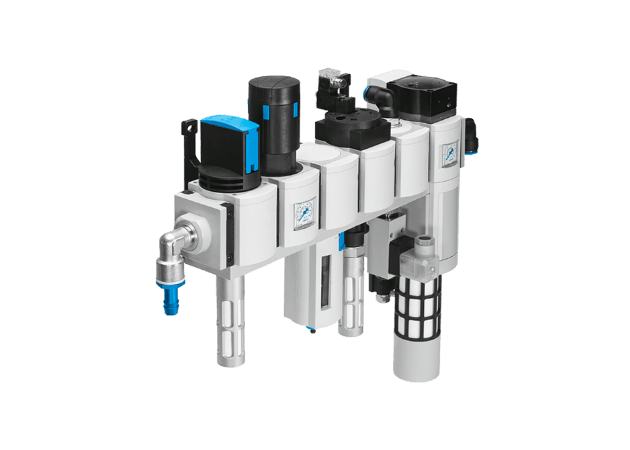

Air Filters

More stories

All cases

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.

The 5-Axis Motion Machine

A 5-axis motion machine incorporates a rotary stage positioned on top. This machine is a significant breakthrough for our client, as it opens up new possibilities in X-ray and CT imaging for a wide range of objects.

4 Axis Motion System

A combination of standard products, customized products and a custom developed air bearing vertical stage. All axis can be driven and synchronized by LAB’s motion controllers or with commercially available controllers.

Case study with Siemens: Smart Virtual Sensing

This study in collaboration with Siemens shows how implementing smart virtual sensing in our air bearing systems can improve the estimates of critical machine parameters at a low cost.

The 5-Axis Motion Machine

A 5-axis motion machine incorporates a rotary stage positioned on top. This machine is a significant breakthrough for our client, as it opens up new possibilities in X-ray and CT imaging for a wide range of objects.